The Challenge: Stable Temperature Control for Maximum Precision

When producing high-precision micro parts, even the smallest temperature fluctuations can be critical. At UpNano, changes in ambient temperature led to beam displacement in the optical path and deformation of mechanical components. This could result in time-consuming readjustments, reduced production speed, and limited system reliability.

The Solution: TEC Controller with Cascade Temperature Control

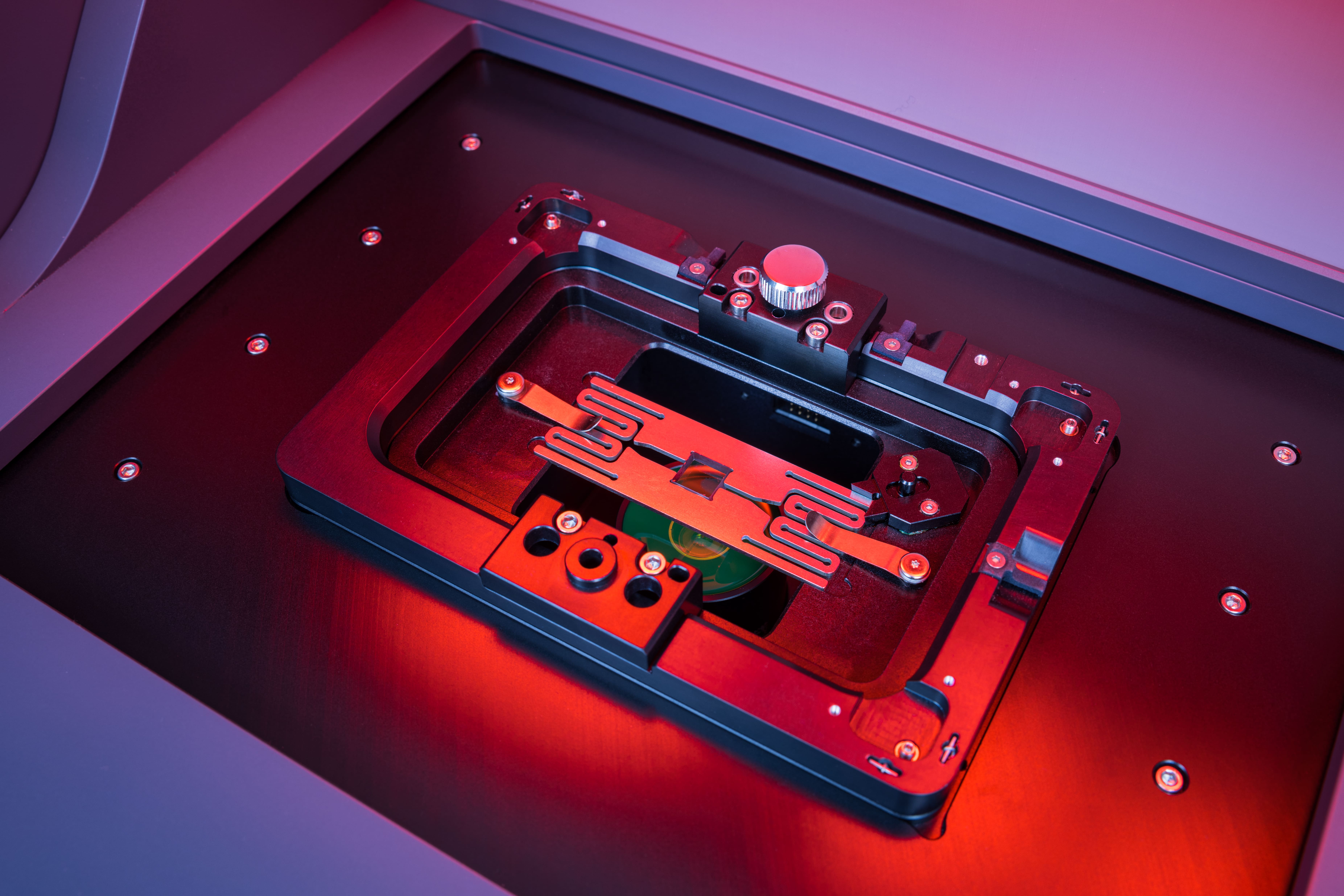

To keep temperature-sensitive components stable in the high-precision 3D printing process, UpNano relies on TEC Controllers from Meerstetter Engineering with activated Cascade Temperature Control.

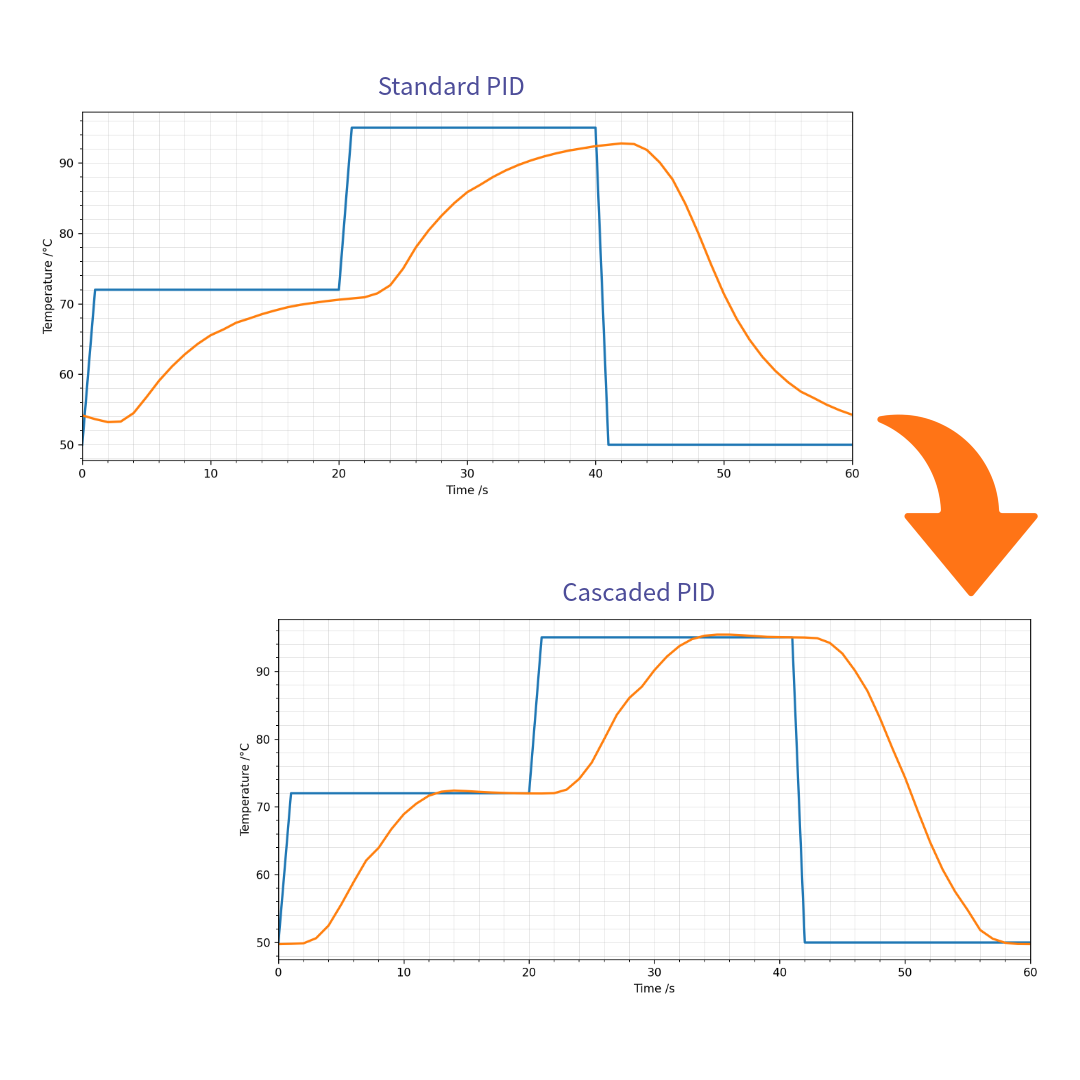

The Cascade Temperature Control of the Meerstetter TEC Controller consists of two nested control loops, whereby the output variable of the inner control loop serves as the reference variable for the outer control loop. The inner control loop is used to control the temperature directly at the Peltier, while the outer control loop controls the temperature at the target object.

This Cascade Temperature Control feature makes it possible to keep the temperature at the critical point constant — even if the thermal system exhibits a certain degree of inertia or is exposed to external influences. This keeps the optical beam path stable and eliminates the need for manual realignment in the event of fluctuations in ambient temperature.

The actively controlled air temperature in the build room significantly reduces the sensitivity of the positioning systems to changes in ambient temperature — by a factor of 20, according to UpNano.

Meerstetter's TEC Controllers offer the necessary control accuracy, can be easily integrated into existing systems and configured, and are also suitable for complex requirements in optomechanical applications.

Technical Highlight: Cascade Temperature Control

Cascade Temperature Control is an advanced control architecture of Meerstetter TEC Controllers. An external temperature sensor located as close as possible to the object to be stabilized is used as a reference for the desired temperature. A second sensor measures the temperature at the point where the heating element is directly thermally coupled, for example, on a cooling block or a heating element. The TEC Controller regulates its output power so that the target temperature at the external sensor is kept constant.

This structure enables very precise temperature control, even in the event of thermal inertia or external interference.

- Stable control directly on the sensitive component, for example on an optical system or a laser module.

- Effective compensation for environmental influences and delays in heat transport.

- Particularly suitable for applications in research, medical technology, photonics, and laser technology.

- Ideal for systems with inert or thermally decoupled components.

Collaboration with Meerstetter: Competent and Customer-Focused

The UpNano development team particularly praises Meerstetter's high quality support: the employees are quickly available, provide competent support during commissioning, and help with performance optimization. Customized versions of the TEC Controllers were also openly discussed, enabling efficient integration into the existing system architecture.

Conclusion: TEC Controller as a Reliable Solution for Demanding Applications

Thanks to the sophisticated all-in-one approach of Meerstetter's TEC Controllers with advanced Cascade Temperature Control feature, temperature control runs reliably, stably, and with low maintenance after initial setup. In the specific application at UpNano, for example, the control ensures a stable temperature for laser-sensitive components in the 3D printing system. This keeps the beam path constant and eliminates the need for manual adjustments.

UpNano therefore highly recommends Meerstetter Engineering — especially for companies that require precise and integrable TEC Controllers for thermally sensitive high-end applications such as laser systems in additive manufacturing.

About UpNano

UpNano GmbH is a leading system and service provider in the field of high-resolution 3D printing technology. The technology used is based on 2-photon polymerization and enables a resolution of less than 100 nm. The company develops and manufactures complete printing systems and printed micro parts, drawing on its proven expertise in laser optics, optomechanics, and mechanical engineering.

Possible areas of application include medical technology, telecommunications, and microfluidics—both in research and industry.

Learn More or Order Directly

Are you looking for a reliable solution for precise temperature control in demanding applications? Then discover our TEC Controllers with Cascade Temperature Control. They are ideal for high-precision systems in optics, laser technology, medical technology, and research.

Or get personal advice – our engineering team will be happy to assist you with selection and integration.