Maximum performance for laser diode drivers with feedforward control: How a load model speeds up the dynamic behavior of the laser diode drivers from Meerstetter by a factor of 10.

The challenge of a PID Controller: Living in the moment

Have you ever imagined what it's like to be a PID controller? You constantly get feedback like ‘too low by X’

or ‘too high by Y’. You adjust the output in an endless loop until you finally reach the target value. It's an

endless cycle of trial and error and with each new target value you forget the previous successful setting. It's a

hard life - living in the moment, without the ability to remember previous successes.

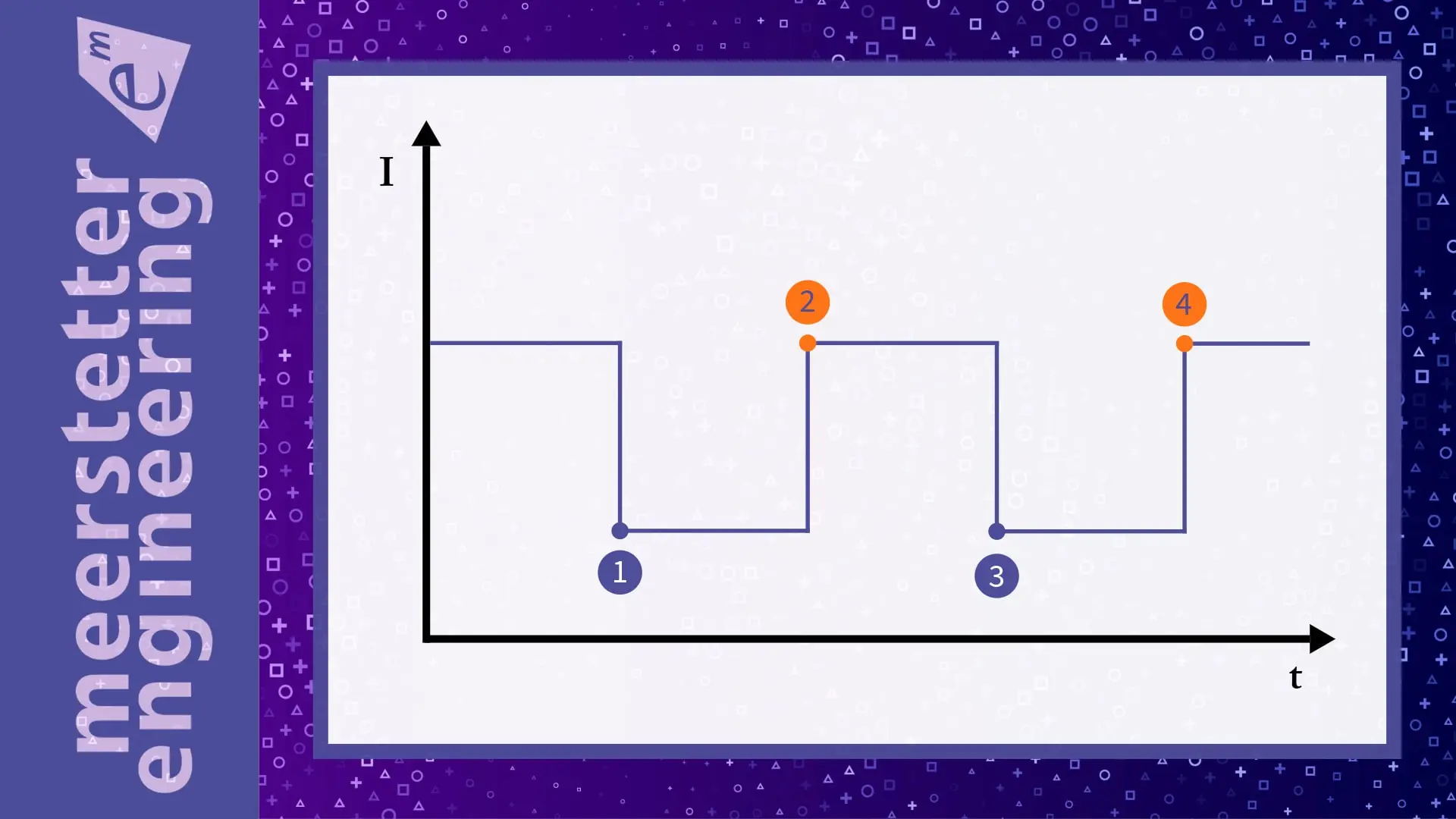

Now imagine that you must control a square signal:

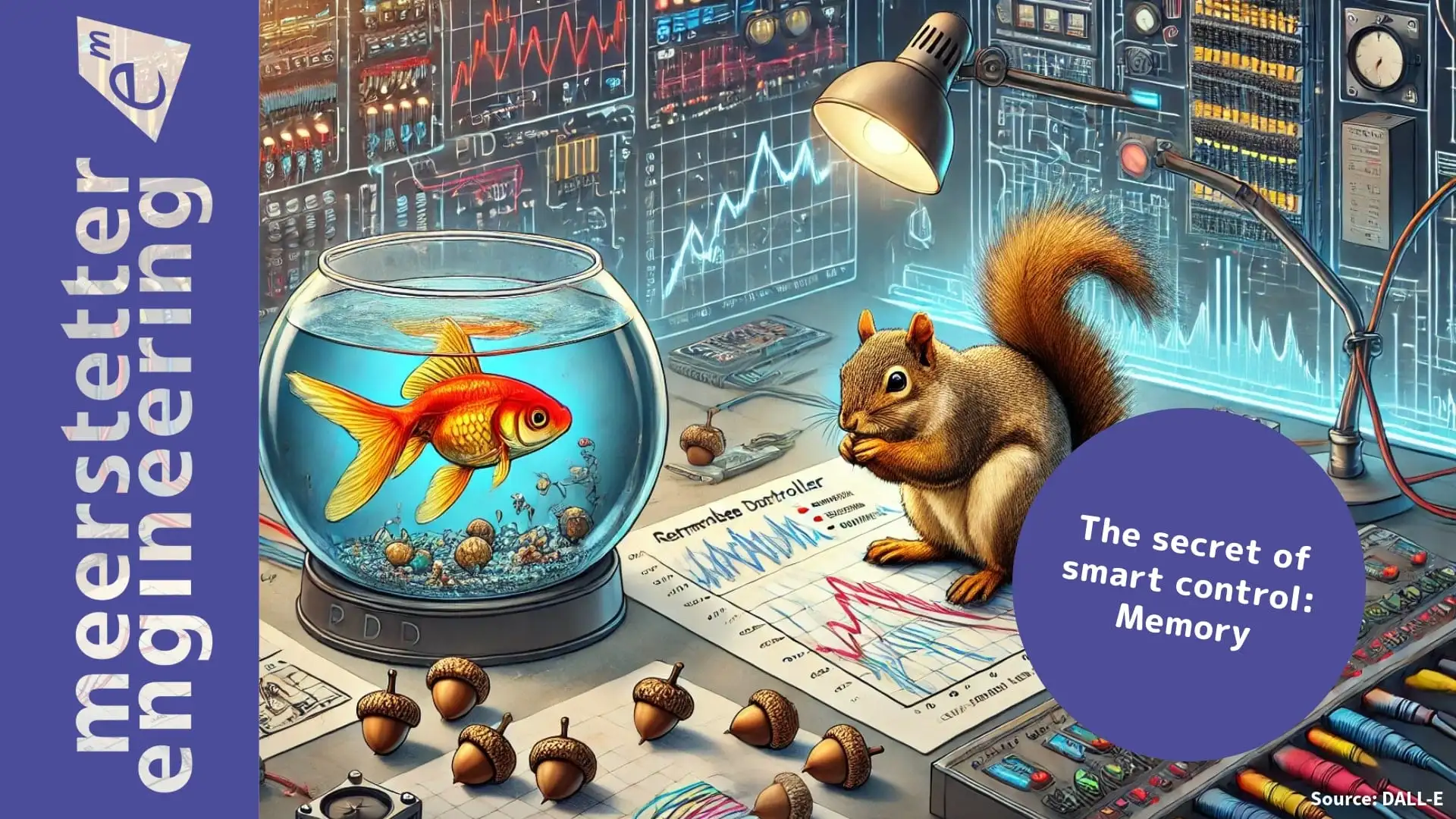

From goldfish to squirrel: How the system from Meerstetter Engineering remembers past successes

In the scenario shown above, the target values are the same in phases 1 and 3 as well as in phases 2 and 4. But by the time you get to phase 3, you have already forgotten what you did right in phase 1. This is exactly what the life of a basic PID control system looks like. Similar PID approaches are also used in Meerstetter's laser diode drivers.

However, Meerstetter Engineering felt sorry for these "poor" PID controllers! They operate like a

goldfish that can't remember past successes.

So, we decided to evolve them - from goldfish to squirrels. Just as squirrels remember where they hid their

acorns, the system from Meerstetter now remembers past output values thanks to the integration of

feedforward control. This makes the control process much faster.

Feedforward control: Precision through predictability

But what about predictability? Laser diodes have a very consistent current-voltage characteristic. This means that if you set a target value of, for example 10 amps, you can predict what output voltage will be required to achieve it. In control theory, this is known as feedforward control - a technique that is not new but is very effective in improving response time and accuracy.

Would you like to find out more about how feedforward control works? Then also read the detailed compendium article.

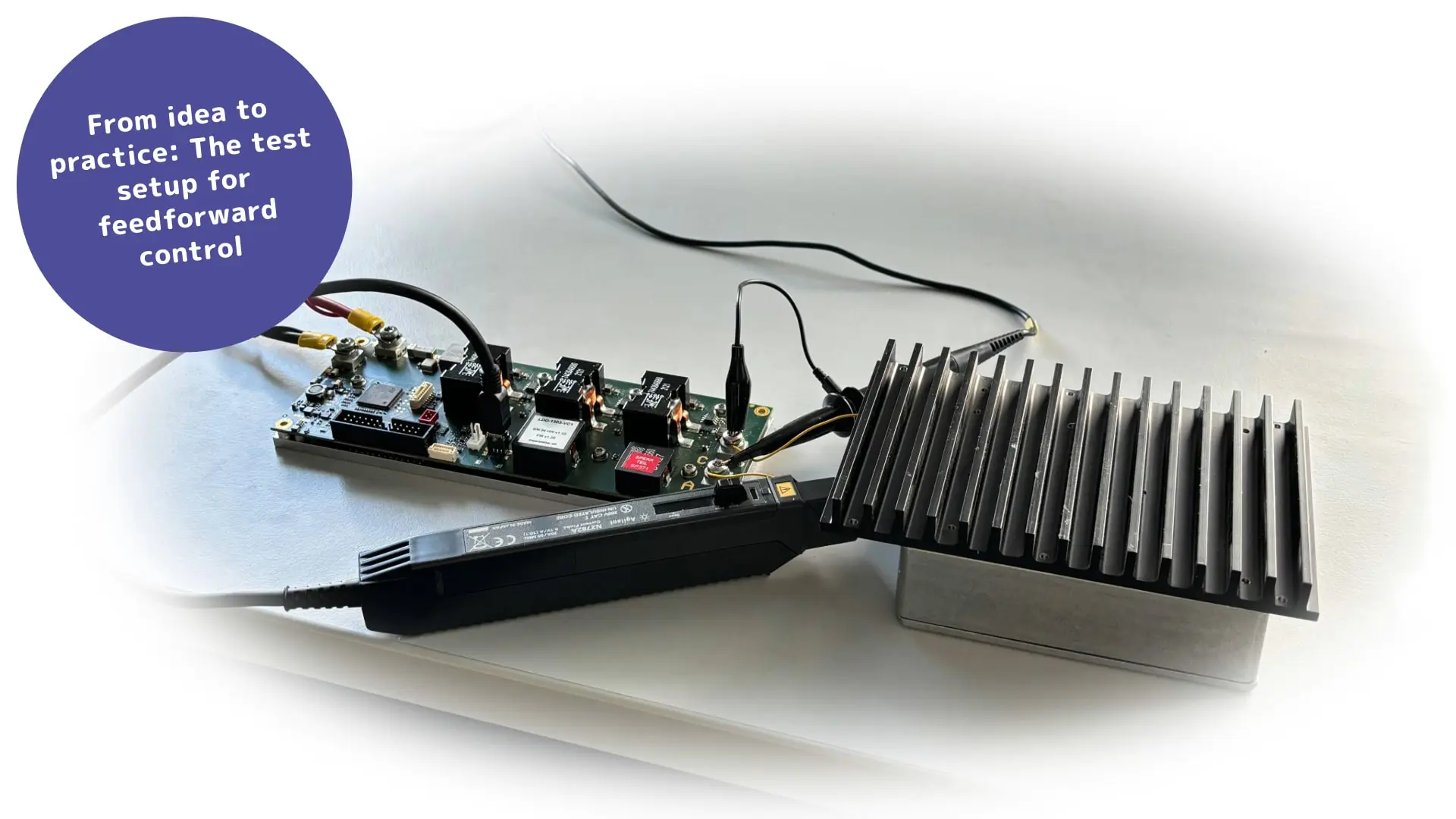

In practice: Laser diode driver with feedforward and PID control

The special thing about the implementation is that you as a user, do not have to worry about modeling the system anymore. Our controller automatically learns the load characterization and derives a parametric description, making the process much simpler for you.

Using a Meerstetter laser diode driver with feedforward control is as simple as that:

- Set the safety limits for maximum output voltage and maximum output current.

- Instruct the controller to record the load characteristic curve.

- Watch the results.

The laser diode driver with activated feedforward control learns, adapts and optimizes the output on its own.

Watch the short video below to see how easy it is to set up feedforward control for PID controllers with our free PC software and read the detailed compendium article to learn more about the different functions of feedforward control.

Conclusion: Up to 10 times faster achievement of the target value thanks to feedforward control and PID controller

By combining PID control and feedforward control, Meerstetter has

significantly improved the performance of laser diode drivers. Thanks to the new ability to measure

and calculate the load characteristic, the target value is reached up to ten times faster than with

conventional PID systems. In concrete terms, this means faster control without manual adjustments.

The integration of feedforward control into the PID controller leads to a significant

improvement in response time, which makes it particularly valuable for pulsed laser

applications in areas such as medical technology, material processing and other high-tech fields.

Try now for free: Experience the power of feedforward control for laser diode drivers

With the update to firmware v2.21, the new feature feedforward control for PID controllers

is automatically activated as a free trial for all existing customers. Newly purchased units will also

have the feature enabled and can be tested free of charge.

At the end of the free trial period, you will have the option to purchase the feature for long-term use.

Contact us for a customized offer, if you have any questions about the new feature, or for a free personal consultation with one of our specialists. We offer you advanced and customized solutions to optimize your product and take your projects to the next level. Together we will master your challenges!

You can find more information on the topic of feedforward control for PID controllers in the compendium article on our website.