The challenge

In high-throughput dairy production, every minute counts. When a filling line halts to verify microbial safety, the entire plant slows down—triggering product ageing, inflated cold-storage costs, and unnecessary production bottlenecks. Traditional microbial testing takes up to 48 hours, forcing operators to extend pasteurization cycles just to be safe—sacrificing speed and efficiency for peace of mind.

Sensip-dx set out to change that. By shrinking microbial test time from 48 hours to just 15 minutes, they enable same-shift decisions that keep production moving. The key enabler? Q-Sens — ultra-thin, real-time heat-flux sensor from Meerstetter Engineering that transforms bio-detection from slow and reactive to fast and actionable.

The solution

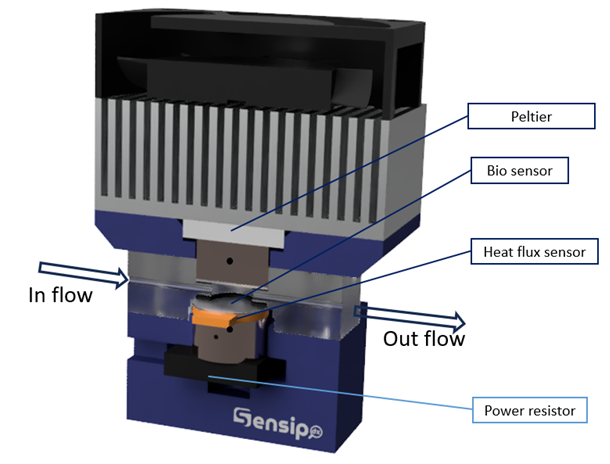

Sensip-dx built a bench-top analyzer with Meerstetter Engineering’s Q-Sens thin-film heat-flux sensor. The instrument compares a surface-imprinted-polymer (SIP) channel with a non-imprinted (NIP) reference while an on-board TEC controller holds the stack at a stable temperature. By directly reading the heat flow, Q-Sens lets the firmware pick out bacterial binding events in real time and deliver a pass/fail verdict within the required fifteen-minute window. Figure 1 places the working prototype in its lab context.

Inside the measurement cell

A coin-sized aluminium disc is coated with a molded polymer that “catches” only the target bacteria; as they bind, they form a thin insulating film. A micro-heater pushes steady heat upward while a Peltier above keeps the temperature fixed. Nestled in between, Q-Sens measures how much heat still gets through: the more bacteria, the less heat. When that drop, compared with an unchanged reference channel, exceeds a preset limit—typically in about 15 minutes—the instrument reports contamination.

Q-Sens integration

Q-Sens sits at the heart of Sensip-dx’s thermal stack, turning an already advanced flow cartridge into a truly quantitative sensor. By delivering a clean, real-time readout of the heat that actually crosses the sensing surface, it strips away drift, trims hardware complexity, and keeps the assay fast even as the design moves from benchtop rig to disposable cartridge.

What Q-Sens brings to the table:

| Feature | Benefit |

|---|---|

| Direct-flux signal | Measures true heat flow in microvolts, so results aren’t distorted by power losses or room-temperature swings. |

| Ultra-thin footprint | Slips between heater and sample disc without adding thermal mass, preserving the 15-minute cycle time. |

| Shared electronics | Its analog output ties into the same Meerstetter controller board that drives the heater and Peltier, eliminating extra PCBs and easing scale-up. |

Those three features allowed Sensip-dx to drop the very same Q-Sens die into early lab prototypes and the cartridge-based production unit — with no redesign.

Discover all the other benefits and advantages of Q-Sens on the specific product page on our website.

Technical support from Meerstetter Engineering

Alongside supplying the Q-Sens heat-flux sensor, Meerstetter Engineering bolstered the project with targeted expertise:

| Thermal-stack simulations | Finite-element models confirmed that the heater-sensor-Peltier stack would stay within the 15-minute assay window. |

| Insight reviews & troubleshooting | On-call consultations translated simulation findings into practical design tweaks and helped Sensip-dx clear unexpected performance hurdles. |

| TEC controller provision & integration help | Meerstetter’s compact TEC controller board was delivered ready-tuned for the cartridge prototype, with hands-on guidance to ensure a smooth plug-and-play fit. |

This focused support accelerated validation while keeping engineering overhead low — illustrating how Meerstetter can pair its Q-Sens sensor with just-enough services to get partners over critical thermal-management hurdles.

Ready to integrate Q-Sens into your own device?

Curious how drift‑free heat‑flux sensing could fit into your own system? Our applications team is ready to show you how easy integration can be.

Request your demo kit today or speak with an applications engineer at sales@meerstetter.ch. Find out more about Q-Sens by visiting the specific product page.