TEC controllers are used for thermoelectric cooling and heating in combination with Peltier elements or resistive heaters. Peltier elements are heat pumps which transfer heat from one side to the other, depending on the direction of the electrical current.

This article describes how heating and cooling is possible with Peltier Controllers.

Heating and Cooling with a Peltier Controller

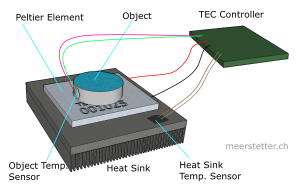

Thermoelectric cooling (TEC) has become the method of choice for fast and compact temperature control. An electrical current through a so-called Peltier element produces an active heat transport. With one side attached to a heat sink, the "object" side of the thermoelectric element can be cooled or heated in respect to the heat sink. A Peltier controller with bipolar output generates the currents accordingly when aiming for a target temperature. To that end, the Peltier controller must know the object's temperature, thus have a sensor input. Primary criteria for the selection of a Peltier controller are its current and voltage ratings, precision and stability. Other important characteristics of a Peltier controller may be its safety features, ease of use (communication, auto-tuning, bundled software), device size and efficiency. Overall efficiency analysis should not only consider losses in the Peltier controller, but throughout all cooling equipment, including the Peltier element.

Thermoelectric cooling (TEC) has become the method of choice for fast and compact temperature control. An electrical current through a so-called Peltier element produces an active heat transport. With one side attached to a heat sink, the "object" side of the thermoelectric element can be cooled or heated in respect to the heat sink. A Peltier controller with bipolar output generates the currents accordingly when aiming for a target temperature. To that end, the Peltier controller must know the object's temperature, thus have a sensor input. Primary criteria for the selection of a Peltier controller are its current and voltage ratings, precision and stability. Other important characteristics of a Peltier controller may be its safety features, ease of use (communication, auto-tuning, bundled software), device size and efficiency. Overall efficiency analysis should not only consider losses in the Peltier controller, but throughout all cooling equipment, including the Peltier element.

Peltier Controller TEC-1089

Thermoelectric (Side) Effects

Thermoelectric coolers are constructed of alternating junctions between n- and p-doted semiconductors. Subjected to electrical current, the desired heat flux will be generated (Peltier effect). However, the Peltier element's capacity to cool is not infinite: the more current the Peltier controller delivers, the more Joule heat is generated all conductors, including the thermoelectric element. This is a parasitic heating effect that will completely cancel out the desired cooling effect above a certain threshold. In practice, this means that a thermoelectric cooler driven near its maximum current rating may hardly cool at all. This has also an impact onto the choice of Peltier controller architecture. To supply a 10 A / 10 V element with, say, 6 A, a low cost PWM-based Peltier controller capable of switching 10 A will provide 0 A for 40% of the time and 10 A for 60%. Besides potentially introducing electronic noise, the Peltier controller is ineffective during 40% of the time and the TEC module is ineffective during 60% of the time. However, if a more advanced TEC controller with DC output is chosen, the Peltier controller is working at its nominal efficiency (85% and more) and the Peltier module is working under optimal conditions.

Heating and Cooling Power Management

Another reason why a thermoelectric module only possesses a limited cooling power is thermal conductivity: the larger the temperature difference between the cold and the hot side, the greater amount of heat seeks to equilibrate—by thermal conduction through the TEC module. The auxiliary input of a Peltier controller is used to measure the sink side temperature. A good Peltier controller will take it into account and predict heat flux. A hot sink helps when the target object temperature needs to be raised, as less electrical current is required for heating. The efficient Peltier controller will be aware of the asymmetry between the heating and cooling powers currently available and will manage accordingly. (The main reason to implement power management routines into a Peltier controller are not energy conservation concerns, but optimal, more stable performance).

The Meerstetter Peltier Controller

Meerstetter Peltier / TEC controllers are advanced thermoelectric temperature controllers, available at different current ratings as compact single and versatile dual channel models. Each Peltier controller channel is a DC current source with a virtually ripple-free output that will drive a Peltier element under optimal conditions. Every Peltier controller channel features a precision object temperature acquisition input (Pt100, Pt1000, NTC) as well as an auxiliary sink temperature input (NTC). The Peltier controller will use optimal power householding (see above) to heat and cool most efficiently. Auto tuning and configurable temperature stability indication are available, and a convenient software suite allows users to monitor and configure all Peltier controller parameters (such as current values, model parameters and safety limits).